QUALITY CONTROL (QC)

· These are the series of checks that are carried out when making a product

· They check that each step of the manufacturing is to a specific STANDARD

· A SAMPLE is taken to be tested by QUALITY CONTROL for example, 1 item in every 100 made.

· Things such as SIZE, COLOUR, WEIGHT or FORM/SHAPE are checked

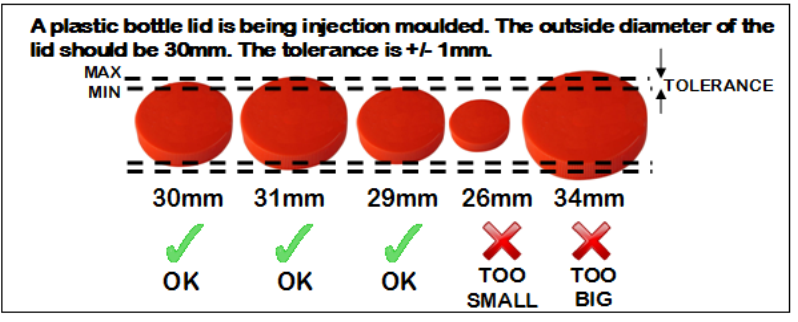

· A TOLERANCE is the maximum and minimum size allowed for an item, for example;

· They check that each step of the manufacturing is to a specific STANDARD

· A SAMPLE is taken to be tested by QUALITY CONTROL for example, 1 item in every 100 made.

· Things such as SIZE, COLOUR, WEIGHT or FORM/SHAPE are checked

· A TOLERANCE is the maximum and minimum size allowed for an item, for example;

· Once the checks have been passed, often a sticker is applied to show that the item has met all quality standards.

QUALITY CONTROL IN PRINTING

· When items are printed in INDUSTRY the following quality checks are carried out:

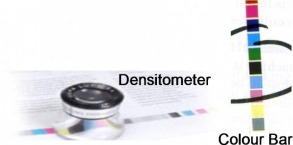

COLOUR BARS

· These are printed down the side of sheets (to either be hidden later when the net is folded or trimmed off)

· The colours consistency and density is checked using a DENSITOMETER

· The colours consistency and density is checked using a DENSITOMETER

REGISTRATION MARKS

· These ensure that the colours (CYMK) are correctly aligned. They should appear solid black.

VISUAL CHECKS

· The typeface and text is checked for breaks (gaps) and that it is clear & readable. The colours are checked against a proof (the original document).

QUALITY ASSURANCE (QA)

· These are the SYSTEMS in place before, during and after manufacture.

· It tries to achieve CONSISTANCY in the quality of all products made.

· Factors such as Equipment, Materials, Processes and Staff Training are all constantly MONITORED.

If QC and QA checks aren't carried out, this will increases waste (poorly made products will have to be thrown away). This in turn increases the COST for the company.

· It tries to achieve CONSISTANCY in the quality of all products made.

· Factors such as Equipment, Materials, Processes and Staff Training are all constantly MONITORED.

If QC and QA checks aren't carried out, this will increases waste (poorly made products will have to be thrown away). This in turn increases the COST for the company.