MANUFACTURING TECHNIQUES

You need to know how Graphic Products are manufactured in industry. This section has information and games on all the processes you will need to know.

(Further MANUFACTURING links at bottom of page!)

CAD, CAM, CIM

· There is usually a question every year based on this area!

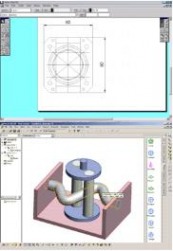

CAD

· COMPUTER AIDED DESIGN. This is the process of INPUTTING your designs into the computer, for example as a 2D Drawing or a 3D model. Examples: 2D Design, Pro Desktop

CAM

· COMPUTER AIDED MANUFACTURE. This is when you convert your CAD drawing into co-ordinates for a machine to follow and OUTPUT. The machine then manufactures your product following your CAD drawing exactly.

Advantages of using CAD/CAM

Quicker than traditional drawing & manufacturing techniques

Gives a much higher degree of accuracy (tolerance) on manufactured products

Easier to make changes, eg update the design, change the dimensions as you just alter the CAD drawing which controls the CAM machinary

Reduced staff costs as less workers needed to operate machinary

Better standard of Quality Assurance as the manufacturing process is identical every time

Disadvantages of using CAD/CAM

Very high cost initially to buy the machinary

Need to employ highly skilled staff to operate CAD & CAM

If the machinary breaks down, the entire production line grinds to a holt, loosing the company money

Disadvantages to local community surrounding the factory as there will be less low skilled jobs on offer

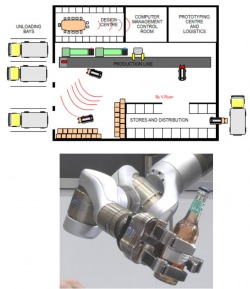

CIM

· COMPUTER INTEGRATED MANUFACTURE: This is where computers and robots control every single aspect of manufacture. It is used when MASS MANUFACTURING items.

· Computers control ALL aspects of manufacturing, from ordering supplies, operating the machinery such as printing presses, packaging products, applying labels, moving of packaged items and deliveries.

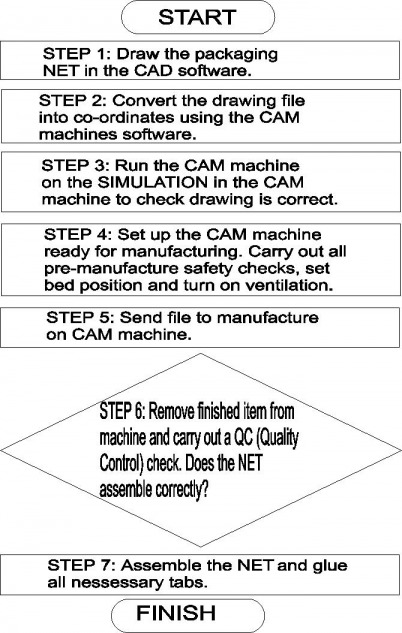

FLOWCHART OF MANUFACTURE USING CAD/CAM.

You are often asked in an exam to draw a flow chart for manufacturing an item, eg a NET, using CAD/CAM. Learn the flow chart, including the flow arrows and feedback loops!

NOW PLAY THE GAME BELOW AND SEE IF YOU'VE REALLY LEARNT IT!

FURTHER MANUFACTURING REVISION LINKS

Click on the links below to go to further MANUFACTURING revision

CAM in Detail; Laser Cutter

CAM in Detail; Vinyl Cutter & Profile Cutter

CAM in Detail; CNC Router

Vacuum Forming

Injection & Blow Moulding

Finishing Techniques and Special Printing Effects

Scales of Manufacture

Quality Assurance & Quality Control