DESIGN TASK: Party Bubbles

Manufacturing Technique: Injection & Blow Moulding

Bottles of bubbles are often given away in goody bags at children’s parties.

You needs to know both how the bottles are manufactured & also how the labels are applied and designed.

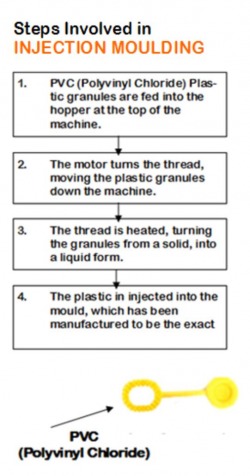

Bubble Blower Manufacture

The bubble blower is made using: INJECTION MOULDING

CLICK HERE to go to images of Injection Moulding Process.

Link opens in a new window

Bubble Bottle Manufacture

All bottles are made using: BLOW MOULDING

If you have learnt the injection moulding technique above, this is easy to remember.

The only difference from injection moulding is that when the plastic enters the mould, AIR is forced into the mould to make a HOLLOW mould, or bottle shape.

CLICK HERE to go to images of the Blow Moulding Process

Link opens in a new window

DESIGN TASK: Bubble Bottle Label

Getting the moulds manufactured for the injection moulding and blow moulding process is EXPENSIVE.

Because of this, manufacturers reuse the same mould over and over again; the just change the colour of the plastic and the label design.

You have been asked to present a series of three labels to be applied to a standard bubble bottle, to a customer. They have provided you with 3 themes: The Farmyard, Clowns & Boats

The products are to be supplied as part of a party multi-pack, and so do not need any packaging symbols or barcode on them.

The NETs have been started for you, you MUST complete them in full using the standard NET given.